Gemini Writes...

Please sign up if you are not a member yet and log in. When you come back to this page, you may download the graphic illustrations of the story.

Integrated Biomanufacturing (2) - What is it you want to achieve?

Often, technology (improvement) studies are non-committing, you just want to make sure you have a grip on what is new and useful out there. Implementation may never happen. Whenever there is a concern for shortage of supply to patients though e.g., due to market demand exceeding the output capability of the production facility or as a result of a portfolio expansion within an existing facility network, implementation of output and efficiency improvement becomes the desired endpoint of your study. The challenge to be addressed needs to be understood and an initial outline of potential financial implications be generated. In biopharma with its complex regulatory framework, improvements often occur in "packages" or coordinated with the introduction of novel products, but rarely as a continuum following the never-ending noise from corporate on cost reduction, and rarely on marketed products (exception see above).

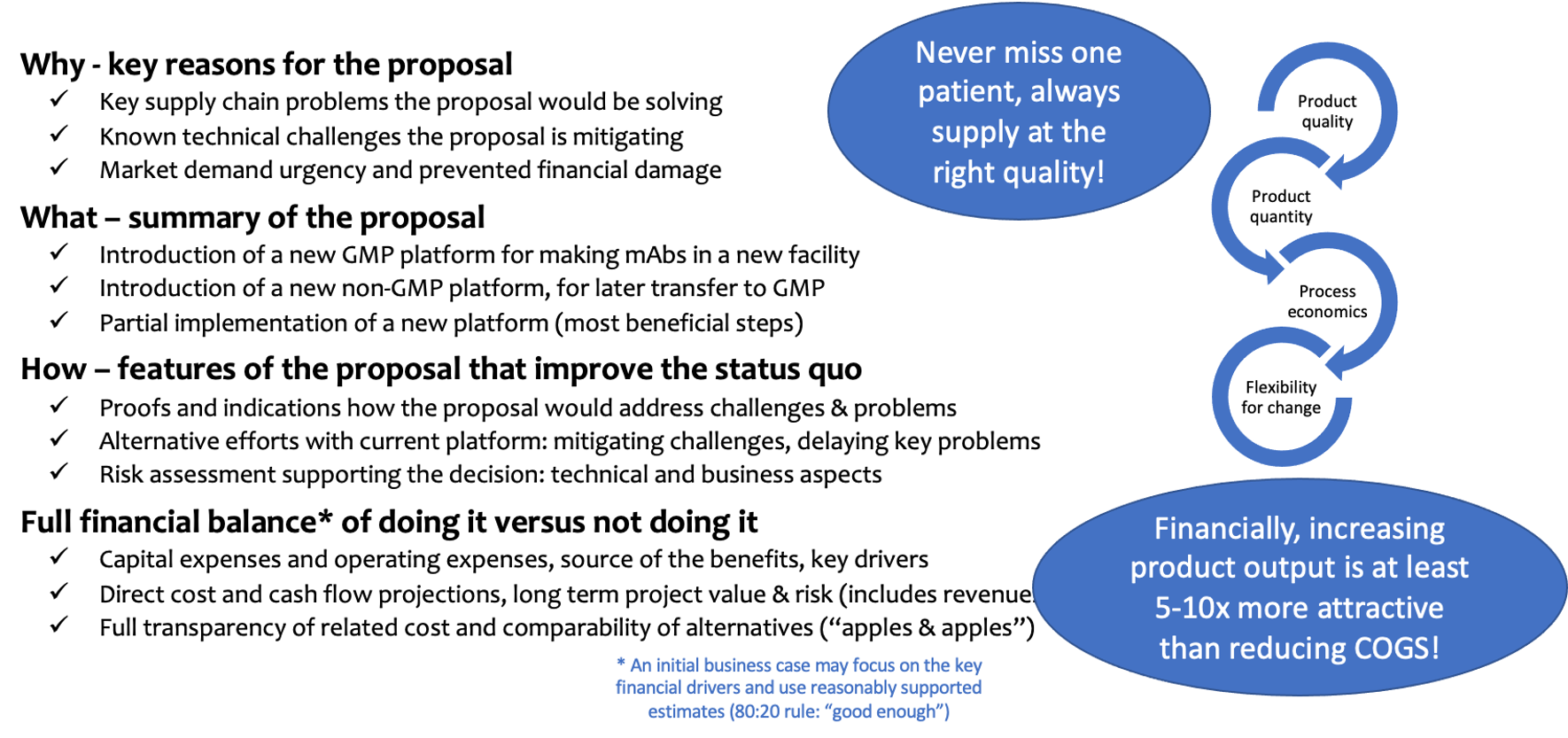

Fig. 3: Elements of a successful business plan.

If you can't explain "why" you are making an improvement proposal with technical AND financial aspects, your case may be dead from start. This is where you get or loose the attention of your (senior) audience. Big numbers and obvious technical bottlenecks may help, but take your time to understand in advance what is considered a relevant improvement in your organization, and what bias may need to be addressed. Facts and science are one thing, but you are in a human environment. Summarise the key elements of your plan, e.g., a production platform upgrade, and explain "what" you intend to do and "how" it is going to work with some illustrative examples. Refer back to the "why" with those examples. Be prepared to answer the question "What did you try to make it work with the existing platform?", not the least because the improvements you propose may change the risk profile for quality and quantity of facility output your management has gotten used to, and possibly also for the time from start of a development to delivery. You will need some level of financial analysis, the more detail the closer you get to the decision on your case, and the bigger the case is.

Fig. 4: Understanding of key financial drivers.

The financial impact of your proposal needs to be above the threshold of significance relative to what your business expects to happen in the foreseeable future. Putting you at the forefront of scientific developments in biomanufacturing alone is not a likely reason for approval of your case. Any risks to achieving the revenues the market offers will get highest priority. Not at any cost, but cost can be an acceptable burden at common price levels for biotherapeutics. Ultimately, what you need to achieve to make a case successful will be scenario dependent: COVID-19 vaccines are an extreme case, all new technology (e.g., mRNA, extreme cold chain, supply chain for 7-8 billion patients in an ongoing pandemic). Anything allowed, cost limits removed, and still unbelievably complex and ambitious (look for video link on GeminiLinks). That's not your most likely scenario. Your business may need extra capacity to meet a growing market demand for an approved, popular drug or to match the forecasts on portfolio expansions from ongoing R&D and business development work. Thus your proposal may need to achieve process improvements that allow the existing manufacturing network of your company to continue delivering whatever product you own. This is often referred to as process intensification or "do more with what you have", lowering operating expenditure and avoiding capital expenditure! Alternatively, your proposal may need to support the kick-off of a novel manufacturing approach leaving behind many of the old ways and keeping only the best elements of the past, combined in a new facility. You achieve the lowest capital expenditure in such an engineering project, when you build small and flexible, and when you consider single-use technology (SUT) in an environment with reduced need for clean rooms. Successful scale-down from previous legacy levels requires the same productivity improvements as for the scenario where you want to keep the existing plant going for some more time.

You will want to present a business case addressing these elements with clear solutions. Next we will go through some selected examples of prioritised process modules that could get you there ... to be continued.