Gemini Writes...

Please sign up if you are not a member yet and log in. When you come back to this page, you may download the graphic illustrations of the story.

Integrated Biomanufacturing (1) - Introduction

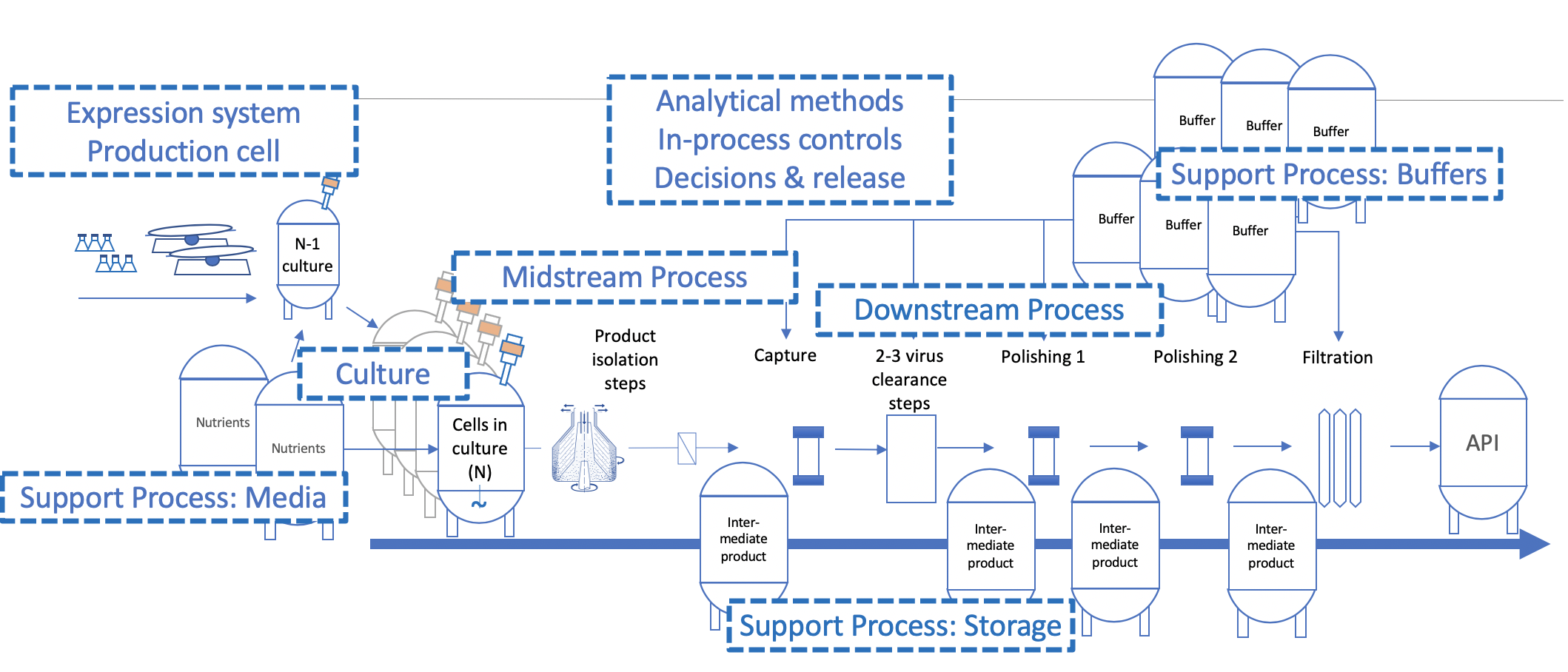

Process development used to be split between upstream & downstream, early- & late-stage teams and analytical scientists & manufacturing engineers. All teams were lacking sufficient awareness of views and priorities in any of the other teams. Between the automation in the lab and in the manufacturing hall, there is still often no connect, neither a common use of data, for example. Because we are so entrenched in scientific speciality, each discipline is going to its own meetings where we practice our incantations, invent new acronyms to cloud the field and make best friends strictly within the family. However, successful development of the most efficient process probably requires instead to be close friend with the other disciplines involved...its a team effort. Though many steps are taken, manufacturing of biologics must be considered as one process! A sketch of this concept is shown below:

Fig. 1: Integrated biomanufacturing overview with essential modules to be linked and optimised.

While each of the modules shown here may be optimised independently, whatever is done may have consequences further downstream but also on how steps further upstream are delivering intermediate product. Suboptimization does happen in such a complex matrix of steps and parameters. It may thus be good to remind ourselves of a principle that sometimes gets pushed aside when novel technology is hyped up to dominate improvement projects and the public discussion, sometimes for years - What is it that drives productivity?

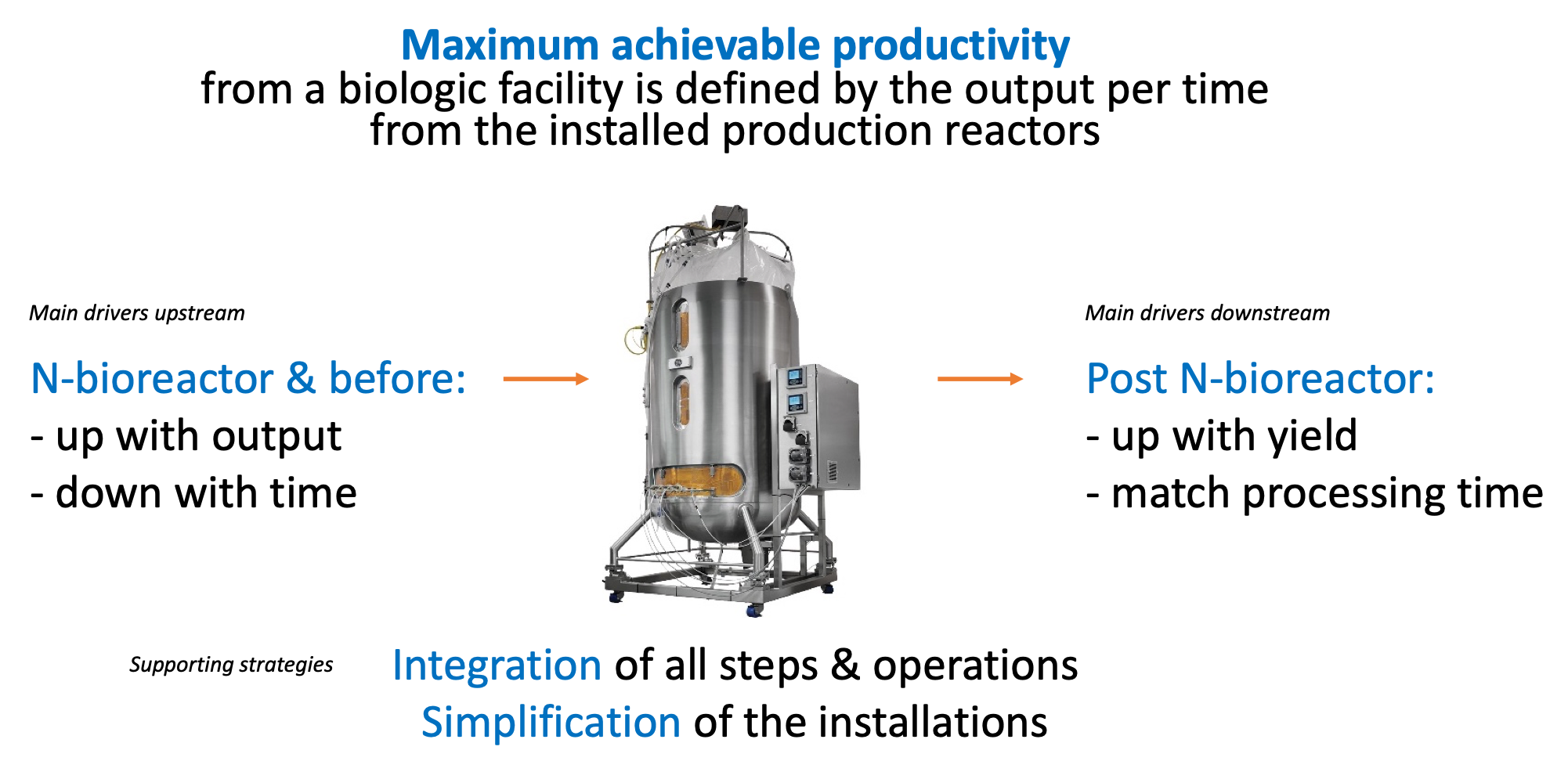

Fig. 2: The fundamental rules of productivity improvement

There is no way that product quantity can be higher than what is delivered from the bioreactors installed in a facility, and the speed not faster than the time they need to deliver it (at least when we assume that none of us went to Hogwarts School of Witchcraft and Wizardry to get her degree from there). Productivity increase happens upstream in the production reactor (N) and possibly with support from the steps before it. Productivity preservation happens downstream from the reactor, mainly via yield increases, sometimes via faster processing of volumes. Highly productive downstream steps may perform better at this than previously used legacy technology, but it is not a given. Neither is any economical advantage of such novel methods in Manufacturing, even though you may find both biopharma R&D and technology vendor bias for them in the discussions you engage in.

This is particularly important to remember whenever an improvement approach leads to more complex and customized setups of equipment and controls, i.e., potentially violating one of two supporting strategies - Simplification! We believe it is key to keep all aspects of manufacturing including all options of linking them in mind following the second support strategy - Integration! Before going into details about advanced design concepts in the different modules lets therefore recap another ground rule: you need to be clear about your answer to the question - What is it you want to achieve? We will devote a separate chapter to it ... to be continued.